Being an HVAC technician can often mean you are in small, dark and potentially dangerous locations. More often than not, you are also alone while in these places. Who is looking out for these workers and how do you ensure an HVAC worker’s safety?

The Heating, Ventilation and Air-Conditioning (HVAC) industry are companies mainly engaged in the installation, repair and continued maintenance of heating, ventilation, air-conditioning and refrigeration systems. The industry operates on three levels; residential HVAC, commercial HVAC, and industrial HVAC.

HVAC Jobs and Legal Requirements

The HVAC industry is well represented across the world, however the U.S. Energy Information Administration states that more than 90% of households in the US have air conditioning equipment, compared to just 8% of the 2.8 billion people living in the hottest parts of the world.¹ These figures are surprisingly high as the Bureau of Labor Statistics shows there are currently 380,400 people employed as Heating, Air Conditioning, and Refrigeration Mechanics and Installers ² across 118,012 registered companies within the United States. ³

The Occupational Safety and Health Act was brought into existence in 1971. As a result of this, the Occupational Safety and Health Administration (OSHA) was created to ensure safe and healthy work conditions across America through setting and enforcing workplace standards. There are specific standards that apply to the HVAC sector such as those applying to ventilation (29 CFR 1926 Subpart D 1926.57) ⁴, fall protection (29 CFR 1926 Subpart M 1926.501 ⁵ and 1926.502) ⁶, personal protective equipment (29 CFR 1910 Subpart I 1910.132) ⁷ and permits required for working in confined spaces (29 CFR 1910 Subpart J 1910.146 . ⁸ All of these standards need to be implemented by employers to ensure HVAC OSHA requirements are met and technicians are working in the safest environments possible.

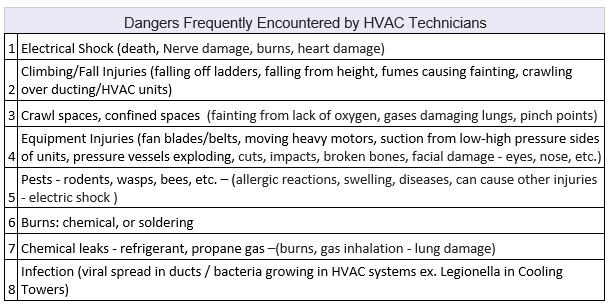

Dangers of Being an HVAC Technician

As shown in the above table, HVAC technicians are frequently exposed to myriad dangers. Electrocution is a common cause of injury and sadly death in the HVAC community with workers being exposed to live wires and high voltages. Falls and equipment injuries also claim lives while technicians are in dangerous locations.

One more danger to HVAC technicians in the United States could be the massive imbalance between the number of units needing to be installed and maintained compared to the number of trained technicians able to do the job. This could easily lead to workers cutting corners or not doing proper risk assessments due to the volume of work they have to complete.

HVAC Safety

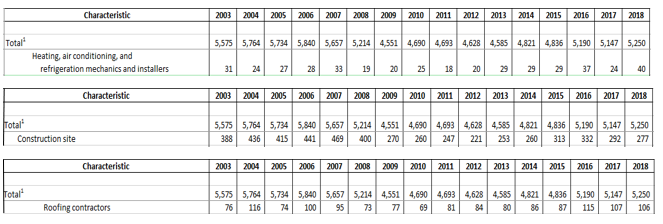

HVAC is considered one of the safer sectors of the skilled trades with a much lower fatality rate than construction or roofing. In the 2020 statistics from the Bureau of Labor Statistics the United States show HVAC as an industry with a fatality rate of 5.1 per 100,000 full time workers. This is significantly lower than other trades, especially when compared to Construction trades – 43.3 and Roofers – 47.0. ⁹

The Census of Fatal Occupational Injuries (CFOI) has published data on fatal occupational injuries for the United States since 1992. Below are the fatality figures for HVAC, Construction and Roofing between 2003 and 2018. Each total is shown underneath the year specified and the total number of occupational fatalities for the country as a whole.

Top Features of an HVAC Safety App

HVAC technicians need to have a safety solution to keep them in contact with others while they are working, especially if they are alone. A great HVAC safety monitoring App has features designed to make it easy for workers to get help if they are in trouble. The top three features that all HVAC safety apps should have are; Man (Worker) down, High-risk check in and a Help button.

The Man down (Worker down) feature should have the capability to alert a fellow worker, supervisor or call centre personnel if there has been no movement from a worker within a set length of time. This could help indicate if the technician has been involved in an accident. This feature should alert management that there has been an incident and therefore the injured party will not have to wait for the next shift to start or for someone to notice they are missing, before being found

Being able to change the time between check in’s if going into a situation deemed high risk is important. The high risk check in feature benefits lone workers in the HVAC industry especially. The ability to set the time period for their check in from between one minute to one hour (in 10-minute increments) allows a technician to adjust the feature to be beneficial to the specific activity they are doing. For a higher risk activity, such as interaction with cables in a confined space, it should be set to a shorter time. Once the task has been completed without incident, the check in time should revert to the normal frequency previously set for the worker.

An HVAC safety app runs on a worker’s smart phone and allows lone workers to check in at regular intervals or request help if they need it. The ‘Help Button’ should send an alert to a supervisor, security personnel or a representative of the employer, informing them that a worker needs assistance immediately. The help button should have options to trigger it; being pushed manually or triggered using voice commands. Workers should also have the option of sending a written or voice message directly to the person monitoring their situation. The employee monitoring App should have GPS capabilities that can locate a technician if they activate the ‘help’ alert.

Conclusion

In order to protect technicians there needs to be a focus on HVAC health and safety. Workers need to carry out risk assessments and follow company safety policies and employers need to implement and ensure OSHA HVAC requirements are being followed. Workers being sent into dangerous locations and situations need a way of summoning immediate help, something that lets management know there is an emergency even if they themselves can’t.

1 – https://www.mordorintelligence.com/industry-reports/united-states-hvac-services-market

4 – https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.57

5 –https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.501

6 – https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.502

7 – https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.132

8 – https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.146

9 – cfoi_rates_2020hb, U.S. Bureau of Labor Statistics, Current Population Survey, Census of Fatal Occupational Injuries, December 2021.

10 – Miscellaneous CFOI data tables, All worker profile, 2003-2018, https://www.bls.gov/iif/oshcfoi1.htm#2020

As an expert in lone worker content management, I possess an extensive knowledge base and experience in the area of lone working and safety monitoring. My expertise in this field encompasses a wide range of areas, including risk assessment, training, communication, and technology. I have a deep understanding of the unique risks associated with lone workers and have researched and written many projects and articles to educate people in how to mitigate these risks.

Throughout my time with Ok Alone, I have kept up to date with technological developments, legislative changes and regulations that have been introduced to help organizations ensure the safety of their lone workers.