Oregon OSHA Heat Illness Prevention Rules

A Comprehensive Guide to Worker Safety

On May 9, 2022, Oregon adopted two permanent rules, 437-002-0156 and 437-004-1131, designed to protect workers from the dangers of extreme heat caused by weather. Rule 437-004-1131 applies to agricultural workplaces, while 437-002-0156 governs all other industries. Both rules exempt indoor environments with mechanical ventilation systems maintaining a heat index below 80°F (26.6°C). These regulations, which use the heat index as a guiding metric, aim to prevent heat-related illnesses such as heat exhaustion and heat stroke, while also reducing risks of workplace accidents related to heat stress.

Understanding the Heat Index

The heat index combines air temperature and relative humidity to represent how hot it feels to the human body. Oregon OSHA's heat safety rules apply when the heat index reaches 80°F (26.6°C) with stricter measures enforced at 90°F (32.2°C) or higher. This proactive approach ensures workers are protected under varying heat conditions.

Access to Shade

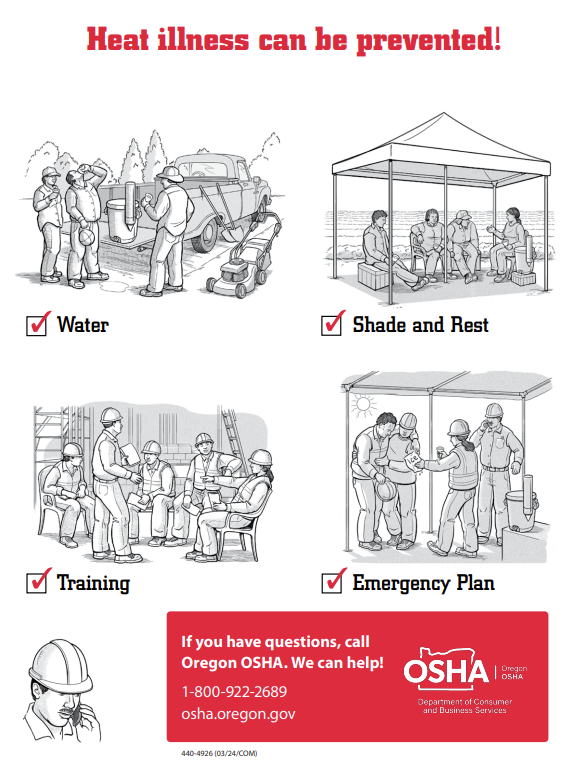

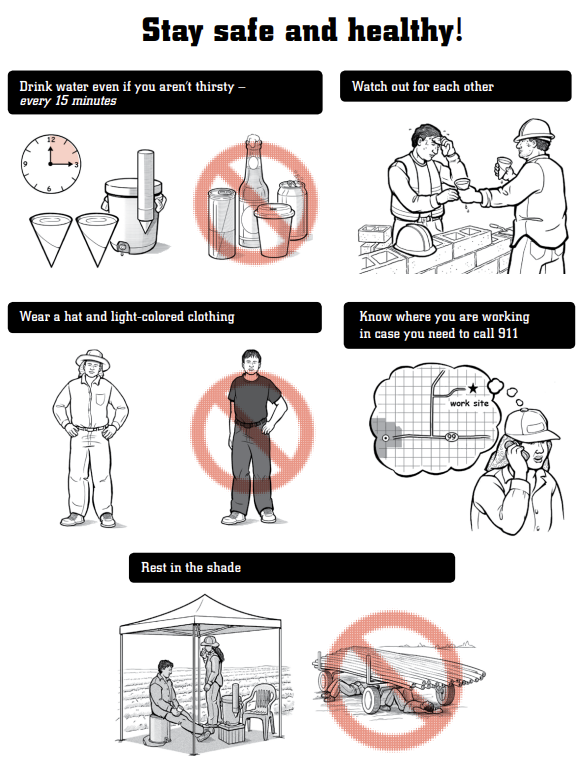

Employers are required to provide shaded areas when the heat index equals or exceeds 80°F (26.6°C), ensuring workers can cool down during breaks. Shade must be ventilated, located close to work zones, and large enough to accommodate all employees on rest or meal breaks. If providing shade is not possible, such as during high winds or mobile work, alternative cooling measures must be implemented that provide the same level of protection.

Adequate Hydration

Employers must supply enough cool or cold drinking water for each worker to consume at least 32 ounces (946 ml) per hour. Acceptable alternatives like electrolyte-replenishing drinks may supplement water but cannot replace it entirely. Employers can begin shifts with less water if reliable procedures are in place to restock supplies as needed.

Annual Training

Training is a cornerstone of the heat safety rules. Employers must conduct annual sessions for all staff in a language employees fully understand, covering:

- Environmental and personal risk factors for heat illness.

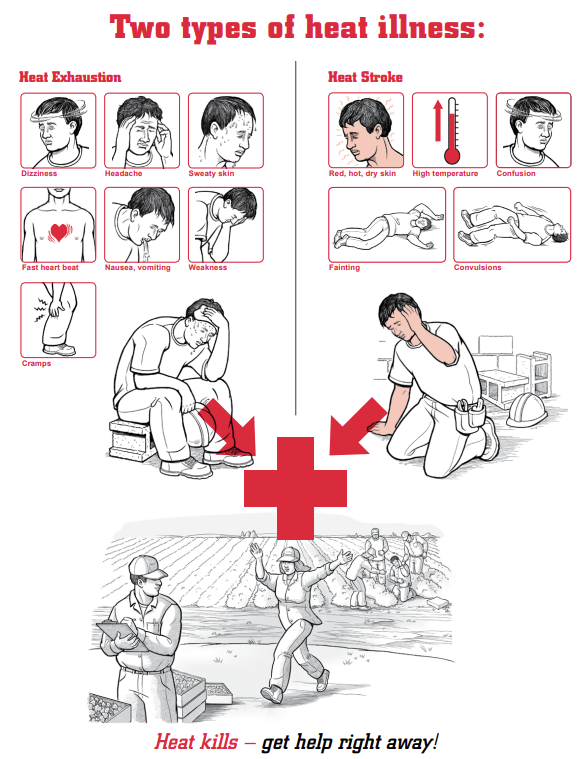

- Symptoms of heat-related illnesses, such as cramps, exhaustion, and stroke.

- The importance of hydration and acclimatization.

- Procedures for accessing shade, water, first aid, and reporting heat illness.

Employees performing "rest" or "light" work under 90°F (32.2°C) are exempt from training requirements but must still be aware of general heat safety provisions.

High-Heat Practices

When the heat index exceeds 90°F (32.2°C), additional high-heat protocols are mandatory and employers must implement additional safety measures:

- Communication: Maintain effective contact between employees and supervisors using methods such as buddy systems, supervisor observations, or frequent check-ins, such as those offered by an employee safety monitoring app, for those working alone.

- Monitoring: Observe workers for signs of heat illness through regular check-ins or on-site monitoring.

- Mandatory Rest Breaks: Workers must take cool-down breaks, lasting at least 10 minutes every two hours when temperatures are above 90°F (32.2°C). At 100°F (37.7°C) or higher, these breaks must be extended to 15 minutes every hour. Breaks can coincide with meal or rest periods as long as they remain effective in cooling down workers.

Workers can combine regular check-ins, panic buttons, and worker-down features within an employee safety monitoring app. These apps can be downloaded directly to a smartphone, eliminating the need for staff to carry additional devices. Packed with safety features like GPS locations and timed activity check-ins, these apps, like Ok Alone, provide an extra layer of protection for staff who need it most.

Emergency Preparedness

Employers are required to have an emergency medical plan for responding to heat illness. This plan must include:

- Procedures for recognizing and addressing heat-related symptoms.

- Immediate actions for severe cases, such as providing cooling measures.

- Designated personnel who must be equipped to contact emergency medical services.

- Clear and precise site directions for emergency responders to locate affected workers quickly.

In severe heat illness cases, such as disorientation or unconsciousness, supervisors must act immediately to ensure the employee’s safety, including offering on-site first aid or arranging emergency medical care.

Acclimatization

Acclimatization is critical for reducing the risk of heat illness, especially for new employees, those returning after absences, or workers during heat waves. Employers must provide gradual exposure to high temperatures, allowing workers to adjust over a 7–14 day period. This process helps workers build tolerance to heat, which can be lost after only a week of non-exposure.

The best way to help workers acclimatize can be done by following established guidelines from the National Institute for Occupational Safety and Health (NIOSH) or creating a tailored plan.

Preventive Scheduling

In response to rising temperatures, some employers have adjusted work schedules, particularly in agriculture. By starting shifts earlier, workers spend less time in peak afternoon heat, reducing the likelihood of heat stress. This practice aligns with best practices for managing worker safety in extreme heat.

Conclusion

Oregon OSHA’s heat illness prevention rules establish a comprehensive framework to protect workers from the hazards of extreme heat. By emphasizing access to shade, adequate hydration, mandatory training, emergency preparedness, and acclimatization, these regulations provide employers with clear guidance to reduce health risks and promote safer, more productive workplaces. As climate conditions increasingly challenge traditional practices, these rules reflect a strong commitment to worker safety, ensuring proactive measures are in place to mitigate the dangers of heat-related illnesses.

For official documentation from Oregon Department of Consumer and Business Services and OSHA see:

Book a Demo Today

Alternatively, get a free trial of the app

Want to try OK Alone? Click the button below and enter your details. It's free and no credit card is required.